Who makes the best heat pump to install in your home? Good question. The correct answer is, it depends.

We’ve installed hundreds of heat pumps in the SF Bay Area and we’ve measured the results from all of our installations. For a ducted system, which is the most popular and best option for most homes in our area, the most important components are things besides the equipment manufacturer selection. Here’s what we have compiled as the basics for making a heat pump installation decision.

The key thing is not manufacturer choice but great design and installation paired with detailed commissioning. While we have chosen Fujitsu for most of our heat pump installs, for very good performance reasons, we do feel that we can get great performance out of most manufacturers out there. Let’s look at the goals of heat pump system.

Comfort:

- Temperature stratification (floor to ceiling) – Existing homes 3 degress

- Room to room temperature differences – Existing homes 3 degrees from set point

- Low to no noise out of system

- Room pressurization <5 pascals (simple terms = very low room pressures)

Air Quality

- Ventilation rates at 3 full air changes per hour while occupied. That means every three hours your home will have replaced all of it’s air with filtered outdoor air. If using an HRV the energy tax is very small.

- Ducts that are at 0 measurable leakage rates so we don’t bring contaminants in

- Verified air barriers between the attic and home and crawlspace and home. Because the air in those places is not good.

Efficiency

- Delivered performance – deliver 85% of system EER (energy efficiency ratio – btu/watt). (measuring the energy outputs at the grilles to see what actually gets into the home compared to the equipment capacity chart at given outdoor temperature.

Here’s how to get to your goals.

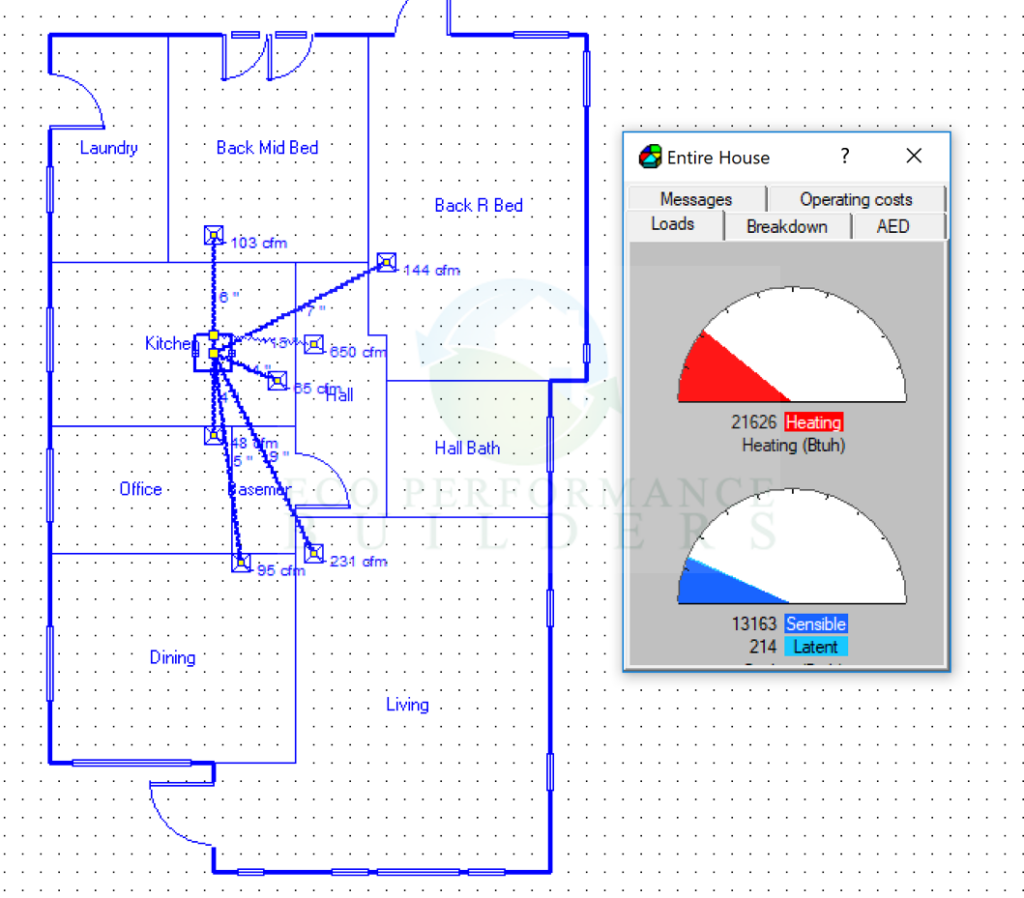

System sizing: The system should be designed using ACCA Manual J. This uses a process where your home is built in a computer program with all of the structure, insulation, window, climate, and building leakage data from your home. We want the system sized correctly to keep system cycling, on-off-on-off to a minimum. The main goal of a heat pump system is to get a small one so if you can air seal you attic and add insulation at the same time, we can use smaller equipment. Smaller equipment in a better performing home will be much more comfortable, quiet, and efficient. The other reason to want a small system is so we can fit the duct work in your home. Most duct systems are undersized and to actually fit the correct sized duct work for the normal huge system is impossible.

One of the main reasons we pick Fujitsu heat pumps, especially for ducted systems, is because they have small btu output units and they’re physically small, which make them perfect for our California homes. In larger homes, we’re able to install two and give a great zoning of the home. We’re also always watching the newest technology from all manufacturers and will switch brands when someone makes a better heat pump.

Duct design and installation quality: The most popular ducted heat pump system today requires very low resistance in the duct work and the design and installation needs to be perfect for them to run efficiently, or sometimes, at all. The more resistance, the more watt draw. In some areas, like attics we are willing to pay for some of the watts to move air faster though.

Ducts should be leak free to keep all energy in and all contaminants out. No brainier right? California law allows for 5% leakage which is not a good standard. Demand a verified zero measurable leakage duct system. We also want ducts as short as possible so we bring grilles in away from the exterior walls to the interior walls. If ducts are in the attic, you want to bury them in attic insulation so they can keep the heat in during the winter and the heat out in the summer. In a crawlspace system, you should think about installing a vapor barrier with low mechanical ventilation. This will keep the heat loss from the ducts more in the home. One more thing to know is flex duct shouldn’t deviate from straight and sheet metal 90’s should be installed at every turn.

Commissioning: A heat pump system, or any hvac system, should be properly commissioned. In our work, it takes the good part of a day to properly commission a ducted heat pump system. What goes into it is airflow balancing with a powered flow hood, measured watt draw, measured duct heat loss/gain, and overall delivered performance. You want to know that the energy out of the grilles is at least 85% of the energy that the system spec sheet said it makes at the given outdoor temperature. This test is almost never done in the HVAC industry but it is probably the most important factor to knowing how to design and install systems for performance.

Final thoughts: If the company you hire to install your system measures all of their work they will know how to design and install better and they will also know what equipment gives the best performance.