When a furnace or air conditioner is installed in a building, it becomes a part of a system. The device’s actual performance – regardless of whatever ratings it boasts – will depend almost entirely on how it interacts with that system.

With that in mind, here are the three most important factors to consider when purchasing an HVAC appliance:

- Size (energy output in BTUs/hr for furnaces or Tons for ACs)

- The duct distribution system into which it will be installed

- The installer

The efficiency ratings (AFUE for furnaces and SEER for ACs) can be important. However, we must remember that these machines were tested in labs, under ideal conditions. In reality, the conditions are much different. For example, if the system’s ducts are leaking 30% of their conditioned air (which is about average), then a 15% difference in AFUE will be negligible by comparison. If you manage to get everything else right, the efficiency rating will then become significant.

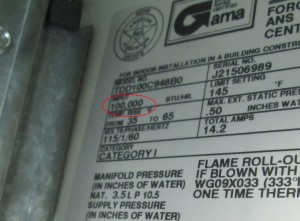

100,000 btu/hr furnace when the house only ended up needing 21,000 btu/hr

Do Not Oversize

The simplest and most important criteria, and yet somehow the most challenging. Most existing furnaces and air conditioners are oversized, which causes serious efficiency loss and durability issues. The question is, why does everyone have oversized HVAC appliances?

There is a tendency to “go big” to ensure the effectiveness of the appliance. An oversized furnace will heat a house noisily, unevenly, inefficiently, and uncomfortably – but it will heat the house.

Standard Heating & Air companies install gigantic equipment all the time. They are not supposed to. They are supposed to measure each window, each wall, the layout of the house, climate data, exterior shade, insulation values etc etc in order to determine exactly how much energy each room (and the house as a whole) needs to stay comfortable. These are called Manual J calculations or heating and cooling load calculations. This takes time and money. So it is much easier to put in an oversized piece of equipment, save time, and do the homeowner a very big disservice.

Also, if the duct system loses a lot of energy along the way (friction, leakage, poor insulation, poor sizing/design) then standard HVAC companies find that they need to over-size the equipment to compensate for a leaky, improperly designed duct system. This is all too common.

Prioritize Correct Sizing Over Product Ratings

Another issue is that sizing options are limited, especially at the low end. Furnaces go down to about 20,000 BTUs, and air conditioners go as low as 18,000 (or 1.5 Tons). Some smaller homes with good air sealing, duct work, and insulation may only need about 10,000 BTUs of heating/cooling power. In this case, we look at other options, such as certain kinds of heat pumps or hydronic air handler systems (see below).

Even if you have a big house, it can be difficult to find exactly the right size furnace. A particular manufacturer might offer three sizes, with very large jumps in the number of BTUs. Typical ACs, on the other hand, always come in increments of 0.5 tons ranging from 1.5 tons to 5 tons, with the same problem (big gaps between sizes).

Because of this, products should be selected based on their size, not their brand.

But This Brand Has Better Reviews!

Reviews and ratings can be a useful tool, but they don’t tell the whole story. A homeowner who writes a bad review for an under-performing appliance will usually blame the manufacturer. But in our experience doing energy audits, we’ve found that poor HVAC performance is usually the fault of the installer.

Manufacturing is done in a controlled environment and is generally consistent in quality. Then reality comes and things change. There are a lot of variables at play with a central forced air HVAC system. This includes duct sizing, friction, airflow, layout, the needs of each room, the sizing of the HVAC equipment, etc. Poor choices in these areas cause poor performance, discomfort, noise, and shortened equipment life.

Common Mistakes and Consequences

High efficiency sealed combustion condensing furnaces are supposed to have two PVC flues, one to exhaust waste gases and one to pull oxygen in from the outside to use for combustion.

When we perform energy audits, we frequently (almost always) find that the installer did not put in the intake vent when one of these furnaces is in a hallway closet. As a result, this high-end, expensive furnace is now drawing interior air and fresh air needs to be supplied to this closet space to provide the furnace with sufficient oxygen. In other words, this closet needs to be somewhat open to the crawlspace and to the attic.

This is a big efficiency loss – the furnace is now sitting in a cold closet in winter, and a hot closet in the summer – either way, it’s working harder to do its job. It also means you’ll have a lot of leakage under that closet door (crawlspace and attic air coming into the house).

Only installed 1 PVC flue (exhaust), not 2nd intake to pull in fresh air from the outside

Worse, if you have a furnace that is not sealed combustion, improper installation can lead to backdrafts. This happens when the home’s pressure is negative, and can result in CO (carbon monoxide, an odorless, harmful waste gas) being pulled into the house.

Air Conditioning and Moisture

Contractors tend to install air conditioners in such a way that they excessively pull a lot of moisture out of the air. This happens when the air is moving too slowly over the evaporator coils. In humid areas, this can be somewhat beneficial. But California has a dry climate. Excessively drying out the air not only takes more energy, but can also lead to respiratory problems in some cases.

If you don’t need an air conditioner, don’t get one. Having one tied in with your furnace decreases the efficiency of your furnace system by impeding airflow. The evaporator coils stuck to the end of the furnace block a good amount of airflow and cause an increase in friction. The effect is small, but not insignificant.

Options for Low BTU Demand (Small Equipment)

Heat Pumps use electricity to provide both heating and cooling, combining two appliances into one. They are great in the following situations:

- Low to moderate power demands, such as smaller homes or homes that have annexed additional space and need to supplement their existing HVAC system. Ductless mini-split heat pumps are appropriate here.

- Homes with no natural gas and where electricity is cheaper than alternatives (propane for example).

- For homeowners who intend to install solar panels, which will offset the electricity demands of the heat pump.

- People who want to plan for the future and be environmentally conscious

Heat pumps have developed a bit of a bad rap. This is partly because electricity is often more expensive than natural gas. But mostly, it’s because heat pumps are very situational, and must be installed properly. When done right, they work very well.

Hydronic Forced Air Heating is another situational option. These are also called Combined Hydronic Air Handler systems. These things also take the place of two appliances – but this time, it’s your furnace and water heater. In a nutshell, hydronic heating uses hot water to heat your home, by running it through coils and blowing air over it. This air is then warmed, goes into the duct system and then into the house. It can be very efficient, comfortable, and more adjustable than a gas furnace.

Variable Speed Fan Means Constant Airflow

Variable speed furnace fan (ECM motor)

A variable speed fan is intended to keep airflow, or CFM (Cubic Feet per Minute), at a constant rate. By using an ECM motor (electrically commutated motor), the fan adjusts its own RPMs to account for varying conditions, such as back pressure. These fans do not vary the airflow as the misleading name may seem to indicate. They also move air generally with a lower watt draw.

Since this can be counter-intuitive, let’s break it down. When we’re talking about HVAC:

- Steady airflow is good (essential, in fact, to any high performance system).

- Variable speed fans keep airflow constant, so they are good.

- Changing airflow is bad, thus, devices that change airflow are bad.

Why is Steady Airflow Essential?

For a specific rate of airflow, there is one ideal duct size. Once a duct system has been carefully designed and installed for specific airflows, they should not fluctuate. If the airflow suddenly goes up, now you have a high friction system. If the airflow suddenly goes down, the air won’t mix with the rooms very well.

For this reason, we generally don’t like to use two-stage or modulating furnaces or air conditioners. Sometimes, we use a two-stage unit if its lower setting happens to match the home’s power demands. In this case, we usually lock it into the low setting, or we allow it to kick into its higher setting only in very extreme conditions (maybe a few days out of a year).

If you’re using the high setting frequently, you’re losing efficiency, and you’re also increasing wear & tear on your ducts (too much friction). In this case, you would do better to beef up your air sealing and insulation and try to keep your machine on the lower setting.

[dropshadowbox align=”none” effect=”lifted-both” width=”640px” height=”” background_color=”#ffffff” border_width=”1″ border_color=”#dddddd” ]For more information, call (925) 363-4498 or e-mail info@epbuilders.com to speak to a technician, or schedule an energy audit.[/dropshadowbox]

Useful Post ! Selecting the right furnace for your home requires careful consideration of various factors, such as size, fuel type, efficiency rating, budget, features, and maintenance. By working with a professional HVAC contractor and understanding your needs, you can choose a furnace that will provide efficient and comfortable heating for your home.